Aernnova Mexico

Integral capacities & capabilities

Aernnova opened Aernnova Mexico in 2008 for the manufacturing of metallic components and the assembly of large complex aerostructures, with the aim of providing better access to the North American market and improved cost competiveness within the dollar area

- Both facilities have the most innovative technologies in sheet metal forming, aluminum alloys machining, surface and heat treatment, paint shops, and the assembly and integration of complex structures. All of this, with the customers approvals and certifications, and having the airworthiness approvals from corresponding authorities.

- We are able to adress complete life cycle of the product: From raw material purchasing management, the internal development of the manufacturing process, design and manufacturing of tooling and assembly jigs, CNC machines programming with a high degree of autonomy and processes vertical integration.

- Aernnova in México manages international programs and is able to accomplish the highest requirements from our customers (OEMs) in an flexible and effective manner. Additionally, product engineering teams are available and able to offer MRB services to the production and assembly lines.

- High expertise and experience in program transition management from other facilities and suppliers located in far away locations to Aernnova (Queretaro), with the posibility of supervision and managing of the Supply Chain.

- Experience in Design & Build programs together with our customer’s working teams, from the first phases of engineering and product development.

Aernnova Aerospace México (AAM)

Complex aerostructures assembly such as wings, empennages and fuselages

-

High level integration of aerostructures (hydraulic, electrical & fuel systems)

-

Integral management capacities & capabilities: Supply Chain, program & projects management, sales and contracting

-

Proven concurrent engineering capabilities

Aernnova Componentes México (ACM)

Metallic components and subassemblies manufacturing for OEMs and Tier 1s

-

ONE-STOP SHOP: Machining, sheet metal forming, surface treatments & related subassemblies

-

Supply Chain Management: Raw Material & Tier 3 Suppliers

-

Type of Products: Fittings, hinges, frames, spars, wing skins & fuselage pannels

-

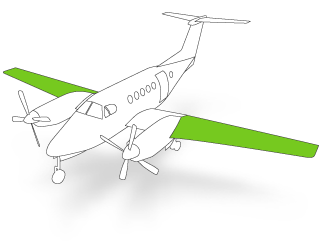

King Air , Baron & Bonanza

Build to Print

- Complete Equipped Wings. Project finalized in 2015.

-

505 Jet Ranger X

Build to Print

- Floor assembly

- Mid-Cabin assembly

- Forward Fuselage assembly

-

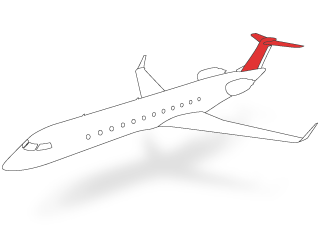

CRJ 700-900-1000

Design & Build

- Horizontal stabilizer

- Vertical stabilizer

- Elevators

-

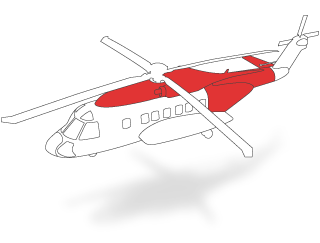

S-92/H-92

Design & Build

- Rear Fuselage (ATT) & Aft Transition Tailcone

- Horizontal Stabilizer

- Engine Cowlings & Main Rotor Pylon (composites)

- Cargo ramp

- Systems: Electric, hydraulics and actuators